THE HISTORY OF SANDPAPER

I previously mentioned in a video how I think 3M Cubitron sandpaper is the best I’ve ever used. They are not sponsoring this article—I'm just saying you should try just one pack. The difference in durability and cutting speed will blow your mind. It's not cheap, but it will actually save you money overall. I'll link below to the great family business where I buy mine if you want to see why I'm giving them this unsponsored plug.

But every time I talk about sandpaper, someone tries to shame me for not using hand planes and scrapers to smooth every surface like a “real” woodworker. They are under the false impression that sandpaper is a modern invention, which the great masters of the past would never have touched because, supposedly, you just can’t get the beautiful surfaces common to the masterpieces of Townsend, Goddard, Chippendale, and others without laborious scraping and planing.

I usually just laugh at those comments because they prove the people making them don’t know half as much about this craft as they think they do.

Today, I’m going to tell you the real history of sanding—a practice that stretches back to the beginning of recorded history and has been an important technique utilized by the finest woodworkers. Whether it be with actual sand, fish skins, or horsetails, I know you’re going to find this far more fascinating than you ever thought an article about sanding could be.

The Early Days of Sanding

The first sanding was done with coarse rocks, including sandstone. There are ancient Egyptian murals that depict workers rubbing wood with sandstone.

There are ancient Egyptian murals that depict workers rubbing wood with sandstone.

Sand itself was also used as an abrasive. Stone could be cut by sprinkling loose sand in a groove and rubbing it back and forth with the edge of a copper plate to create an abrasive saw.

Among the first all-in-one abrasive sheets were natural shark and other rough-scaled fish skins. Another natural product was made by boiling and drying a plant called horsetail. Both of these methods were used by the Romans, and in the Far East, the practice still exists to some extent today.

The Evolution of Sandpaper

Abrasive-coated paper seems to date back to at least the 13th century when the Chinese used natural gum to adhere sand, seeds, or crushed shells to parchment. That may be the earliest example of something we, today, may recognize as sandpaper. As the centuries progressed, other types of abrasives were used, including crushed flint, quartz, and garnet. By the fifteenth century, the Swiss were using paper coated with crushed glass.

Then, the industrial revolution came, and new adhesives were developed. In 1833, a piano maker named John Oakey developed a better process for gluing abrasives to paper to create a more durable sheet that could be mass-produced in large quantities. The cost of sandpaper—at times more than a day's wage per sheet—started to become more affordable for small shops.

As these products made their way into the mainstream, they were often generically called "glass paper," even though any number of natural particles could have made up the actual grit. Industry consumed so many of these natural abrasives that people began experimenting with man-made particles.

Around the end of the 1800s, synthetic silicon carbide and aluminum oxide were developed—the same abrasives that are on many sandpapers today. These synthetic particles made sandpaper abundant and even more affordable.

When Did Woodworkers Start Using Sandpaper?

It’s impossible to pinpoint exactly when wood was first sanded. As I mentioned, the ancient Egyptians sanded wood with stones. Early woodturners were known to use cattails to smooth their work, and various other plants have been used as well.

A French manuscript from the 1400s indicates that a form of sanding was used to refine a surface after using edged tools. It said, “First make the wood very flat and smooth by scraping it, and lastly by rubbing it with that herb which is called shave-grass.”

Another manuscript from the 16th century describes polishing wood with burnt pumice stone, “well rubbed with a coarse cloth and with said powder.”

Another sixteenth-century text makes it clear that the practice was, by that time, already an old practice in woodworking: "For the final smoothing of woodwork, the medieval equivalent of sandpaper seems to have been the rough skin of a dog-fish."

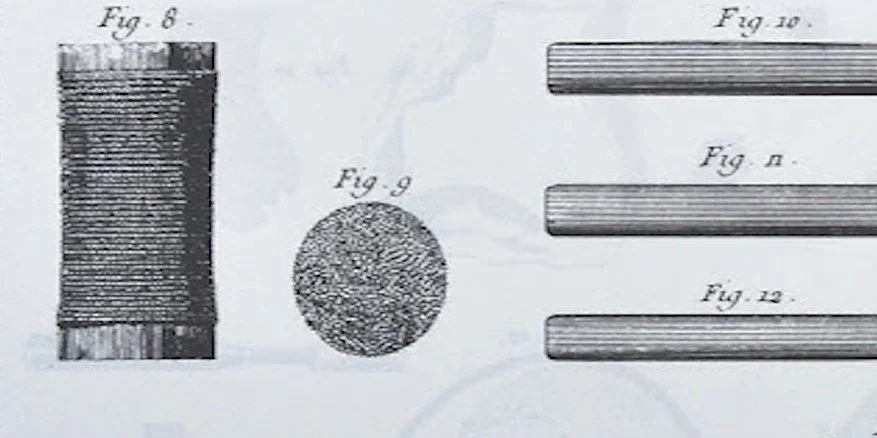

While it’s trendy to think of the popular 18th-century masters using nothing but finely tuned hand planes, André Roubo's 1769 treatise on the craft explains how to make a poli-swa (or polisher) from a bundle of stems, which was used both to abrade and to burnish wood to a fine finish.

A poli-swa diagram, as described by André Roubo in his 1769 treatise on the craft.

Anthony Hay, the 18th-century cabinet maker from Williamsburg, VA, was known to use shark skins to smooth his work.

Surviving texts from the 1700s even teach how to make your own sandpaper by gluing fine sand to brown paper. The result was said to be as equal in quality to fish skins.

Conclusion: Sanding Is Not New

Clearly, the practice of sanding has ancient origins, and some of the finest woodwork that survives in museums today was smoothed, at least in part, with some form of natural or manmade abrasive sheet. So, the next time someone tells you the old-timers scraped and planed everything and would have rejected our modern sandpaper, you can just laugh, knowing that great craftsmen like Townsend, Goddard, Chippendale, and others would have killed for a sheet of 3M Cubitron.

Check out this article where I use the 3M Cubitron discs to sharpen.

(If you use the affiliate links below, we may receive a small commission)

3M Cubitron Sandpaper: https://lddy.no/19fdf

(My favorite is the Xtract mesh, but the multi-hole discs are amazing, too.)

Need some cool tools for your shop? Browse my Amazon Shop for inspiration.