THE TRUTH ABOUT HOLLOW GRINDS: DO THEY REALLY WEAKEN YOUR EDGE?

Millions of people sharpen their tools by grinding them on a round wheel. This isn't a new idea; grinding wheels have been used for centuries. However, as often happens on the internet, it has become trendy to overanalyze and pick apart long-held beliefs, claiming that everyone has been doing it wrong. I’ve heard many people argue that an edge sharpened on a grinding wheel will become brittle or dull more quickly than one sharpened on a flat stone.

The idea behind this argument is that the edge will take on the shape of the wheel. For example, a CBN wheel on my bench grinder will create a curved or concave bevel—often called a hollow grind.

Hollow Grinds

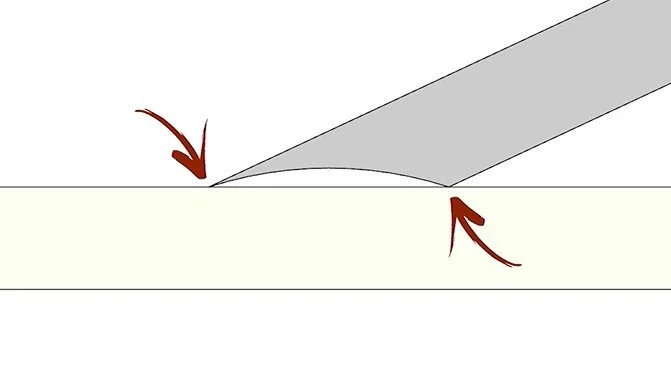

Of course, this isn't some new revelation. Many people actually want that shape from their grinder. As they return to a flat stone for their final honing, they can feel those two distinct points (the edge and the heel) more easily than they could a single bevel. This makes it easier to find and hold the proper angle when freehand sharpening.

Additionally, because only two points are in contact with the stone rather than the entire bevel, less material needs to be removed with those ultra-fine grits to achieve a razor-sharp cutting edge.

“But Maybe You’re Wrong, Jim”

Still, some people argue that when you hollow out the bevel, you create a thinner, more brittle cutting edge. And looking at the drawings people use to illustrate hollow grinds, you might be fooled into agreeing with them. However, these drawings, with their dramatic hollows, are often greatly exaggerated.

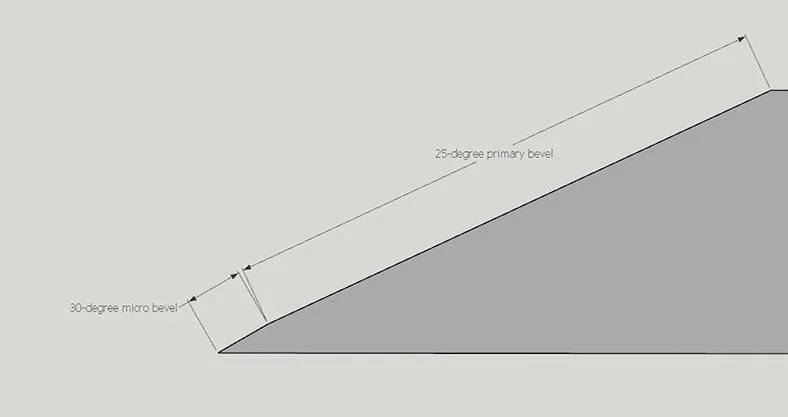

To really understand how a round grinding wheel affects your tool, we have to take a closer look. Below you’ll see a scale drawing illustrating a 1/4-inch thick chisel with a flat-ground 25-degree bevel. It also shows how it might change if that same 25-degree bevel was hollow-ground on a 6-inch grinding wheel. If you used an 8-inch grinding wheel, the difference in shape would be slightly less significant, and a 10-inch wheel even less so.

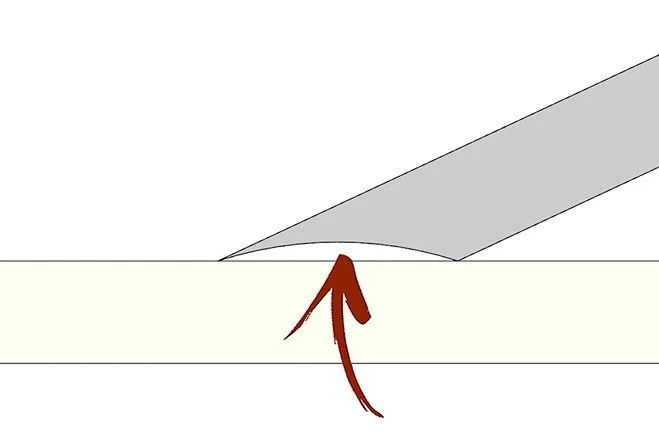

Remember, we’re talking about how the hollow affects the cutting edge. Its effect in the middle of the bevel is irrelevant to the edge’s durability. All that is just mass; the cutting happens at the edge. As you can see in this greatly magnified, but still scale drawing, the actual change to the cutting edge is minimal.

How minimal? For the sake of discussion, let's focus on the effect of a 6-inch grinder, as that small wheel will create the most dramatic hollow you’re likely to get from an electric bench grinder. Let's consider the last 32nd of an inch at the tip of the chisel where all the cutting occurs.

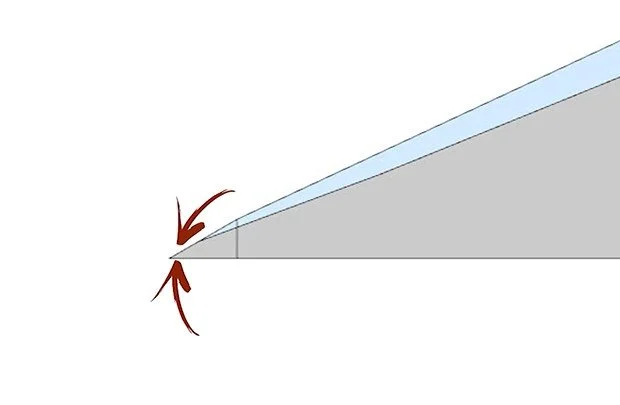

The loss of the blue portion of the bevel due to the hollow grind does appear to alter the cutting edge. My grinder’s tool rest was set to 25 degrees, but the hollowing effect changes the angle at the very edge of the bevel to about 20 degrees. As a result, the steel at that critical cutting edge is a little thinner.

But here's the thing—most tools are only rough-ground to 25 degrees. After that, the final edge is typically honed on a flat, fine-grit stone or other abrasive at 30 degrees. This forms a micro-bevel along the cutting edge, which effectively cancels out the hollow grind and eliminates its thinning effect at the critical area.

Because of this, a hollow grind would have no effect on the durability of a cutting edge if you, like most folks, follow up the grinder with a final honing on a fine-grit, flat stone.

But maybe you don’t do it that way. CBN grinding wheels, for example, are available in very fine grits. Perhaps you’re all about power and never use flat stones. Will a hollow grind really weaken an edge that comes straight off the grinder?

What About Straight off the Grinder?

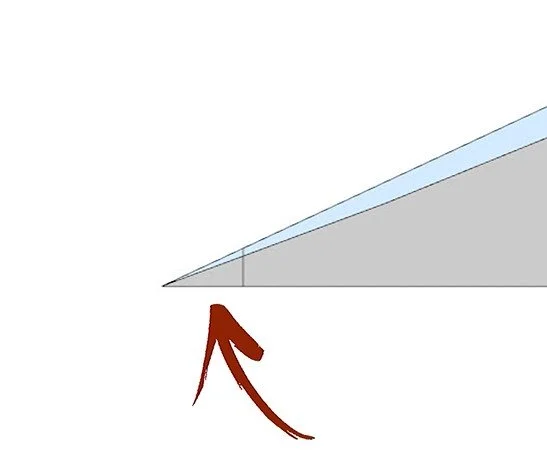

This drawing illustrates a 30-degree grind, such as you might create with a 6-inch wheel when you plan on taking the tool right from the grinder to the work. Again, the blue area represents the effect of the hollow grind as compared to a flat bevel, and the vertical divider represents the 32nd of an inch at the tip where the cutting occurs.

That tiny sliver of blue near the tip tells us that this hollow grind does change the cutting edge slightly by reducing the angle at that point from the intended 30 degrees to about 27 degrees. This also slightly thins the steel, though the percentage of that reduction becomes infinitesimally small the closer you get to the edge. Still, we’re often told that the optimal angle for performance and durability in most woodworking tools is around 30 degrees. And 27 is not 30. But consider this…

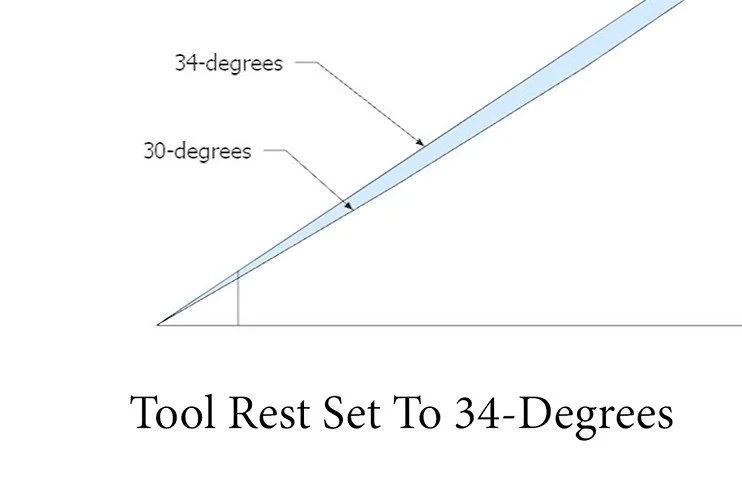

Here, I’ve made a minor modification to my setup by adjusting my grinder's tool rest angle from 30 degrees to about 34 degrees. The blue still represents the slight change caused by a 6-inch hollow grind. But now the effective angle of the remaining steel at the cutting edge is back to 30 degrees, and the thinning effect caused by the hollow grind has been canceled out. In simple terms, we made the edge thicker so we could then make it thinner.

Conclusion

Some folks will still argue, and I doubt this will end the debate entirely. But these scale drawings tell me three things:

A hollow grind has no effect on the cutting edge of a tool when the grinding is followed up by a final honing on a flat stone to add a micro-bevel.

Any thinning effect a hollow grind may cause to the cutting edge—when the tool goes straight from the grinder to the work, with no micro-bevel—can be eliminated by merely setting the grinder's tool rest three or four degrees steeper. Though, in truth, this will only make you feel better and will have little or no effect on the tool's performance based on my experience.

The final point we can take from this study is that when you magnify a drawing, you blow things way out of proportion.

Perhaps that’s the real lesson here: Tiny things can become big problems if we make them out to be so. Just because a problem may exist in theory doesn’t mean it will in actual practice when you put steel to wood.

(If you use one of the affiliate links above, we may receive a small commission)

Tormek T-4 – Compact Water Cooled Sharpening System for Edge Tools

-BOW Featherboards: https://amzn.to/430ldhv

-123 Blocks: https://lddy.no/vpij

-Mechanical Pencils: https://amzn.to/2PA7bwK

-Lumber pencil: https://amzn.to/2QtwZjv

-Pocket Measuring Tape: http://amzn.to/2kNTlI9

-Nut/Bolt/Screw Gauge: http://amzn.to/2CuvxSK

-Self-Centering Bits: https://amzn.to/2xs71UW

-Steel Ruler: https://lddy.no/10mv7

-Center-Finding Ruler: https://lddy.no/10nak

-Bit & Blade Cleaner: https://amzn.to/2TfvEOI

-Narex Chisels: https://lddy.no/sqm3

-Mini Pull Saw: https://amzn.to/2UEHBz6

-Shinwa Rulers: https://lddy.no/zl13