THIS SIMPLE WOOD FINISH WILL SAVE YOU DAYS OF SHOP TIME! (SHELLAC)

For centuries, shellac was widely considered the best wood finish in the world. Then, modern finish manufacturers convinced us that shellac was old-fashioned. “That’s what your grandfather used! The modern woodworker uses polyurethane!”

I’m not here to bash polyurethane—it has its place, for sure. But many woodworkers have forgotten why shellac is such a great finish. Today, I’m going to explain why you should be using it, how to use it, and when to use it.

There are other videos and articles about shellac out there, but this one will be the best because I’m going to answer a lot of questions that others seem to ignore. By the end, I can almost guarantee you’ll want to get out to the shop and put some shellac on something.

Why Use Shellac?

First, why would you want to use shellac as a wood finish? For one thing, it is fast and really easy to apply! You simply wipe it on. You can’t mess it up because it dissolves itself. If you miss a run somewhere, you can fix it when you apply the next coat.

Shellac also dries incredibly quickly. You can start the next coat immediately after the previous one, which means you can complete the entire finishing process in a few minutes or hours, depending on the size of the project, rather than waiting days for a finish to cure.

Shellac will adhere to almost any other finish, and almost any other finish will adhere to it—provided it’s the dewaxed variety. For example, some folks like to put shellac over tung oil or boiled linseed oil for extra protection. Others put polyurethane over their shellac, water or oil based, and it will stick.

Because shellac dissolves with alcohol, it is very easy to repair—even years later. It’s also safe for the environment, as it’s made from the excretion of the lac beetle and contains no petroleum products. In fact, pure shellac is used as a food coating—it's why your M&Ms melt in your mouth but not in your hands.

Shellac also smells nice. It’s great for inside drawers and cabinets, where natural oils or petroleum-based finishes may give off unpleasant odors when you open them.

Finally, shellac comes in different colors, ranging from light blonde to orange to deep brown—all depending on the type of tree the beetle was feeding on. You can use these colors to your advantage to bring life to dull, kiln-dried wood like walnut or add a mellow, aged look to lighter woods like pine or maple. You can even add aniline dyes to create custom wood stains.

Why Isn’t Everyone Using It?

To summarize, shellac is one of the most beautiful, fastest to apply, hardest to mess up, simplest to repair, and easiest to clean up finishes out there. So why isn’t everyone using it on every project?

Part of the reason is that it doesn’t produce a bulletproof, plasticky shell like polyurethane or other modern finishes. Shellac can be durable—it's been used for centuries on floors, for example. But since alcohol will dissolve it, it's not the best finish for high-use surfaces like tabletops.

But I think the real reason shellac isn't more widely used anymore is because people are afraid of it. This is strange because it’s so easy to use. But when they see people using digital scales to weigh flakes and carefully measure alcohol, they think it’s easy to screw up. It’s not! It’s actually very simple once you understand a few key points. Let me explain.

How to Get Started with Shellac

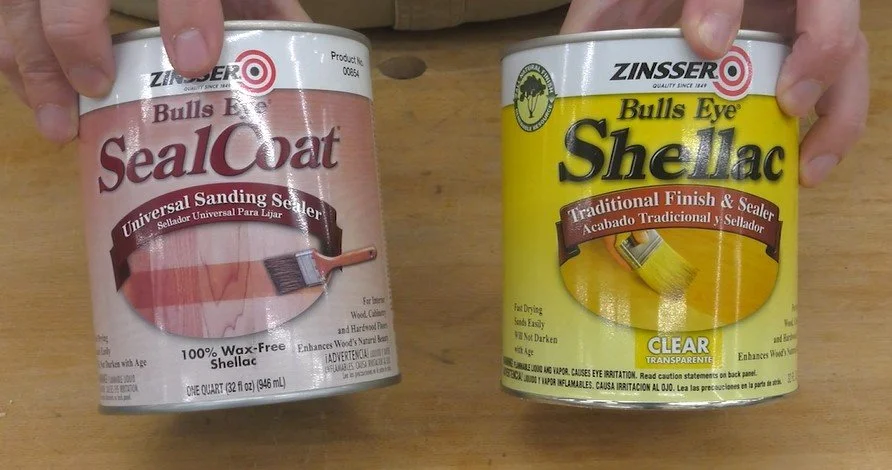

The easiest way to start using shellac for the first time is to buy it pre-mixed in a can. Most stores sell two versions: one labeled Seal-Coat and the other simply labeled Shellac. You can finish an entire project with either of these—they are both shellac. But there are some differences you need to know about.

Seal-Coat is extra-thin shellac. In professional terms, this is considered a 2 lb cut, which means 2 lbs of shellac flakes dissolved in 1 gallon of alcohol. It’s extra-thin so it will soak deeply into the wood fibers and harden. This partially seals the surface of the wood, allowing stains to absorb more evenly, which is why it's called Seal-Coat. Some people refer to it as sanding sealer. But it's not just an undercoat for wood you intend to stain. You can use it as your entire finish; it will just take more coats to build up a protective layer.

The can labeled Shellac contains a higher concentration, a 3 lb cut, which is equivalent to 3 lbs of shellac flakes dissolved in 1 gallon of alcohol. This is 50% more concentrated than Seal-Coat. However, it’s not usually used at full strength. Most people will dilute it with 30-50% alcohol, depending on how thin you want your coats.

Over time, you’ll develop your own preference for how you use it. But as a general guide for a new user, I would consider Seal-Coat ready to use, while the other Shellac is a concentrate that needs to be thinned. Since denatured alcohol is inexpensive, the concentrate may be cheaper in the long run. However, if you have trouble finding pure alcohol in your area, Seal-Coat may be the better choice to start with.

Dewaxed vs. Waxed Shellac

Another thing to consider when buying canned shellac is whether it’s waxed or dewaxed. Natural shellac contains wax, which is fine if all you plan to do is apply another coat of shellac or perhaps some paste wax. But if you want to apply something else on top, like stain, lacquer, or polyurethane, you’ll need to use dewaxed shellac. Of these two options, only Seal-Coat is dewaxed. You can put something over this, but you can’t put something else on top of the waxed version.

Shelf Life of Shellac

The shelf life of canned shellac is something to keep in mind. They say it lasts 3 years in the sealed can, but I think it lasts significantly less after you open it. The older it gets, the slower it will cure. Some woodworkers consider it bad after just a few months, while others tolerate it for longer. As a rule, don’t buy it until you need it, and if you have leftovers, mark the date it was opened. If you still have it 6 months later, test it on some scrap wood before you use it again. If it’s still sticky after a few minutes or gums up your sandpaper, it’s time to toss it.

When buying shellac, you should know how old it is. Zinsser, for example, uses codes for the dates. The first letter identifies the plant it was made in. The first number is the last digit of the year it was made (e.g., “9” for 2019). The second number is the month (e.g., “8” for August), and the last two numbers are the day. So, a can labeled with a “9” and an “8” with a “D” would indicate it was made in December 2019.

Making Your Own Shellac from Flakes

If you want to skip the shelf-life issue altogether, you can buy shellac flakes, which last indefinitely as long as you store them properly. Once dissolved in alcohol, the clock starts ticking, and they’ll go bad in about 6 months. But you have the flexibility to make only what you need for your current project, reducing waste.

It’s really not difficult to make your own shellac. I like to use a 2 lb cut (2 lbs of flakes per gallon of alcohol). But I rarely need a full gallon, so I use a 4-to-1 ratio. That means four times the liquid measurement in ounces of alcohol compared to the weight measurement in ounces of flakes.

For example, if I want to make about a quart of shellac, I mix 32 oz of alcohol with 8 oz of flakes (8 x 4 = 32). This will make slightly more than a quart because the flakes take up space even after they dissolve, but the ratio is still 4-to-1.

Applying Shellac

Applying shellac is incredibly easy. You simply wipe on a thin coat. You can use a brush, but I prefer a soft cloth like an old t-shirt. Alternatively, you can make an applicator by wrapping cotton balls inside a small piece of cloth, tying it off to keep it dense but not hard.

The best part about shellac is that it dries so quickly. The alcohol flashes off in seconds, leaving the shellac to harden in just a couple of minutes. In fact, you can usually start the next coat immediately after finishing the last one.

Conclusion

To sum it up, shellac is a fast, beautiful, and easy-to-use finish that produces results you’ll love. It’s easy to apply, repair, and clean up, and it’s environmentally friendly. While it may not be the go-to finish for every project, especially for high-use surfaces like tabletops, it’s perfect for a variety of other woodworking projects.

So, what are you waiting for? Give shellac a try, and I bet you’ll fall in love with it too!

Tools used in this video:

- Coffee grinder: https://amzn.to/3ERazA7

- Digital scale: https://amzn.to/3gtNEkT

- Magnetic stirrer: https://amzn.to/3Ev84SL

- Tiger shellac flakes: https://amzn.to/3OpGOcK

- More wood finishing videos: https://youtube.com/playlist?list=PL-gT7JMZFYje9AEX4bPTmWUZV9qyZRYi9

Please help support us by using the link above for a quick look around!

(If you use one of these affiliate links, we may receive a small commission)