UNDERSTANDING AIR-DRIED VS. KILN-DRIED LUMBER

When it comes to woodworking, one of the most important decisions you'll make is choosing the right lumber for your project. But how dry does it really have to be? And can you trust lumber that you've cut and dried yourself? Understanding the differences between air-dried and kiln-dried lumber is essential for ensuring the success of your project. After all, nobody wants to spend hours (or even days) crafting something beautiful, only for it to crack, warp, or split a few years down the road.

This is a technical subject, but I'm going to simplify it for you in the next few minutes. By the end of this post, you'll be better equipped to make the right wood choices than 90% of your woodworking peers.

The Drying Process: Time vs. Control

The biggest factor most people think of when it comes to drying lumber is time. Kiln drying takes days or weeks, while air drying can take months or even years. The goal of drying lumber is to remove as much moisture as possible before you start building with it. The reason for this is simple: once you've turned that wood into a table or cabinet, you don't know what might happen if it continues to dry or absorb moisture after it's been built into your piece.

For most furniture, you want the wood to have a moisture content of around 6-8%.

Understanding Moisture Content

Does that mean 6-8% of your board will be water? This is one of the most confusing parts of this subject, but it's crucial to understand. When we're talking about moisture content, we're actually talking about water weight, not water volume. In theory, a board that is completely dry will have a moisture content of 0%. Makes sense, right? But when it was freshly cut from the tree, it could have been 200% or more.

How can a board be 200% water? Well, it can’t. But it can weigh 200% as much as it would if it were completely dry. So, a board with 6-8% moisture content weighs 6-8% more than an equally sized board with zero moisture in it.

Of course, you would never want a board with zero moisture content. You want a moisture level that is roughly equal to the air around it so it neither swells nor shrinks as it naturally tries to match its environment. Otherwise, it may warp or crack and ruin your project.

Relative Humidity and Wood Moisture Content

These days, most of the things we build will live in climate-controlled homes. And that's what we try to match when we dry lumber for woodworking projects. But wait a minute—if you walk over to your thermostat, it will likely show that the humidity level in your house is about 35%, not the 6-8% I just mentioned. That's because your thermostat measures relative humidity, which is different.

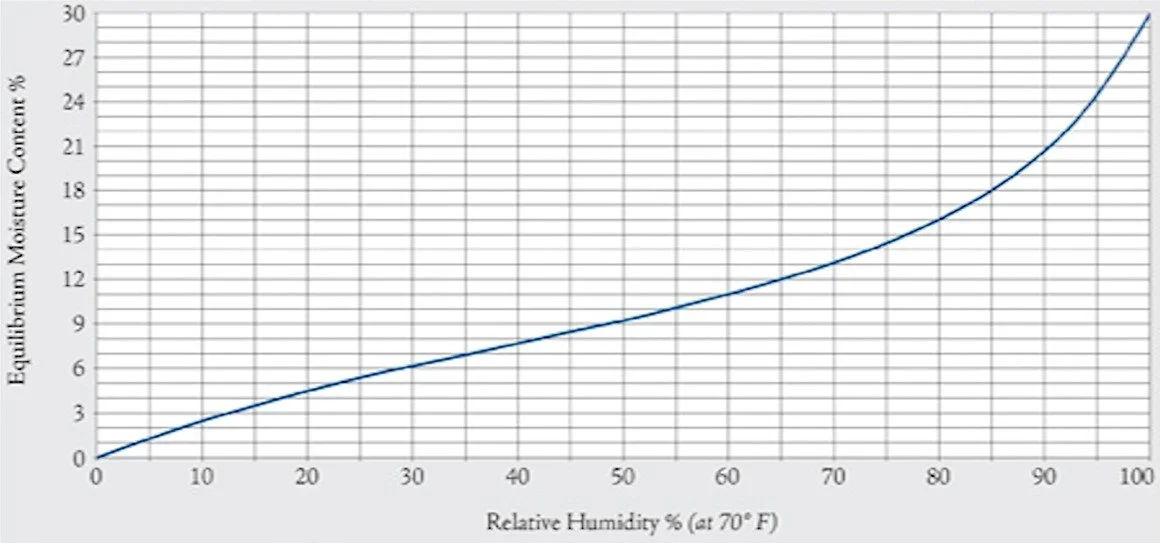

Relative humidity refers to the amount of water vapor in the air compared to how much the air can hold at a specific temperature. If you put the two different standards on a graph, you'll see that the 30-45% relative humidity found in most climate-controlled homes is compatible with the 6-8% moisture content standard for wood.

How to Dry Lumber: Air-Drying vs. Kiln-Drying

Now that we know what we’re aiming for, how do we get there? Can you cut a log into boards, stack it in your yard, and expect it to dry out to 6-8% moisture content? Probably not.

A kiln can easily bring the moisture content of lumber down to whatever you want because the environment inside the kiln is carefully controlled. But air-drying relies on the moisture in the air outside, and that's not something you can control. Even if you keep the rain away, a moisture content of 12-15% is probably the best you can achieve outside of a desert climate.

That’s the biggest downside of air-dried lumber—whether you do it yourself or buy it from someone else. It simply may not be dry enough for furniture projects.

Does This Mean You Can Only Build with Kiln-Dried Lumber?

Not at all. If you’re using air-dried lumber, you might be able to get the moisture content to acclimate a bit more to the relative humidity of the space where the finished project will live. You can do this by stacking the rough lumber in that space with stickers or spacers between the boards and allowing plenty of airflow around the stack. This process can take several weeks, depending on the original moisture content and the thickness of the boards. This is why many woodworkers prefer kiln-dried lumber—it's often ready to go right out of the box.

However, kiln-dried lumber isn't always ready to use immediately without some time to acclimate. In fact, we could make an entire video on the importance of acclimating your lumber before use. The point is, air-dried lumber suffers from higher moisture content and requires more care. I would never recommend grabbing a board from the woodpile and immediately starting your project without checking the moisture content and letting it sit, if necessary.

The Advantages of Air-Dried Lumber

Lest I sound like I'm down on air-dried lumber, let me be clear: there are some real advantages to it. For one thing, it can be significantly less expensive. I've bought plenty of it over the years and saved a bundle. Just be sure it's been a couple of years since it was cut—I don't buy green lumber because it’s so unpredictable.

Keep in mind that you're very likely to have more waste because of the checks, cracks, and warping that occur during the first months of the air-drying process. I've had as much as 50% waste when buying someone else's pile of air-dried hardwood. So, factor that in when negotiating the price.

The Drawbacks of Kiln-Dried Lumber

Kiln-dried wood has its own set of disadvantages. Since humidity affects it to a lesser degree, it can be difficult to steam-bend. If it’s been overly dried, the wood can become hard and brittle, making it difficult to work with hand tools. If the wood was dried too quickly, it can become case-hardened, creating internal stresses that may cause the wood to warp when you cut it. And kiln drying can even change the color of certain woods—kiln-dried walnut, for example, may appear lighter or even purple.

Conclusion: Air-Dried or Kiln-Dried Lumber?

So, should you use air-dried or kiln-dried lumber in your next woodworking project? Personally, I prefer to use kiln-dried lumber, as long as I can trust it was dried properly. If I’m steam-bending or planning a lot of hand-tool work, I might choose air-dried lumber instead. But let’s be honest—price and availability are often the biggest factors. If I have a pile of air-dried lumber, I’ll use it and feel good about the extra money I saved. But I’m also going to take care to ensure it’s dry enough for the project I’m making.

No matter what, always take care to check your wood’s moisture content, whether it’s air-dried or kiln-dried. It’s an important step in ensuring the long-term success and beauty of your project!

★THIS VIDEO WAS MADE POSSIBLE BY★

Fisch Forstner and drill Bits are the best of the best- Still forged the old-fashioned way! : https://amzn.to/3KT440D

My Table Saw and Bandsaw are AWESOME! Check them out at Harvey Woodworking Machinery: https://www.harveywoodworking.com/

My hand tool collection includes premium tools from Bridge City Tool Works: https://bridgecitytools.com/

Please help support us by using the link above for a quick look around! (If you use one of these affiliate links, we may receive a small commission)