THE TRUTH ABOUT 2X4S: HOW BIG LUMBER IS RIPPING YOU OFF

The internet is full of excuses about why a 2X4 isn't actually 2 inches thick and 4 inches wide. Most of these are complete poppycock cooked up in the dark, smoky back rooms of big-box stores. I, for one, am sick of being made a fool of by big lumber. So in this post, I’m going to tell you the truth that has, until now, been spoken only in whispers. This is the real story of why our lumber is shrinking and what you should do about it.

The fact is, the lumber mills have been absolutely ripping you off for years.

A 2X4 Was Once a 2X4

There was a time when a 2X4 actually was a 2X4. If you've ever remodeled an old house, you know what I'm talking about. Today's inch-and-a-half 2X4s and 2X6s look like mere sticks compared to the robust studs of the past.

But if you look closely at the framing in many old houses, you'll see a problem: there wasn’t much consistency. The wood in one part of the house might be around 2 inches thick, while in another part, it might be 2-1/4 inches, or something else entirely. It depended on the mill that cut it, and sometimes even on the mood of the operator on the particular day the wood was cut. If it was Friday afternoon and Hank had a snoot full, you never knew what you were going to get.

This wasn’t a big deal when everyone was building their own houses and nobody really cared how they turned out. But as construction became more industrialized, and building codes started getting involved, these inconsistencies turned into real problems. Imagine framing a wall with studs that weren’t all the same width, or calculating the load limits on a floor when the joists weren’t all of a known thickness.

The Rise of Standardized Lumber

In the first half of the 20th century, the powers that be got together to come up with standard dimensions for commercially produced construction lumber. After some wrangling, him-hawing, and a fair amount of tomfoolery, they devised the biggest shenanigan ever pulled on the American public.

The standard thickness for framing lumber was set at 2 inches, and standard widths included 4, 6, 8, 10, and 12 inches. At least that’s what they planned to tell the public. But the truth was much darker, like a black cat in a lonely alley with no lights.

You see, that back-room boondoggle wasn’t just about standardization—it was also about profits. For example, West Coast mills had a glut of trees waiting to be shipped to the lumber-hungry East Coast. Freight costs, particularly going through the Panama Canal, were based on volume, not quantity. The fat cats figured out they could reduce volume while increasing salable quantity if they made the wood thinner. The profits could be converted into top hats and monocles before the public even knew what hit them.

But how would they convince you and me that we weren’t getting a raw deal? In an act of pure, evil genius, they devised the "nominal thickness" scam. Here’s how it works…

The Nominal Thickness Scam

When you buy a 2X4, you ARE buying 2 inches by 4 inches of wood. That’s the way honest Mr. Miller cuts it from the log. But you don’t want a green, wet board, do you? That might cup and warp before you drive your first nail. So the lumber company is going to do you a favor—they’ll dry that board out for you. Sure, it will shrink a bit, but you want wood, not water, right?

Of course, that nice, dry board might also be a little rough. The edges could be sharp, you might even get a splinter. So the gracious lumber company is going to plane that board smooth for you. They'll even round off the edges so your soft, moisturized hands can handle it.

How much does it take to smooth a rough board? Well, how thick was it to begin with? It may have started as a 2X4, but you never can tell how much shrinkage you’ll get as it dries. And remember, those darn bureaucrats in Washington say every board has to be the same. So just to be safe, the mill is going to take 1/4 inch off every surface—faces and edges. And in a final act of kindness that totally has nothing to do with misleading anyone, they will still call it a 2X4 so you don’t have to strain your tongue saying something as awkward as "pass me that 1-1/2 X 3-1/2."

You're welcome.

Why Not Cut It Thicker to Start?

Now, I know what you’re thinking. It’s understandable that wood shrinks when it dries, and it sure was nice of them to make it smooth and straight. But why not just cut the boards thicker and wider in the first place so they end up being 2 inches by 4 inches after all that drying and planing?

You're asking the right questions, and here’s the answer straight from industry insiders: The equipment didn’t work that way. At least it didn’t back in 1964 when nominal thicknesses were introduced. Apparently, they were still using old mills that couldn’t be set to cut just a little bit thicker than 2X4 inches, and they didn’t want to waste a lot of wood planing down to those standards.

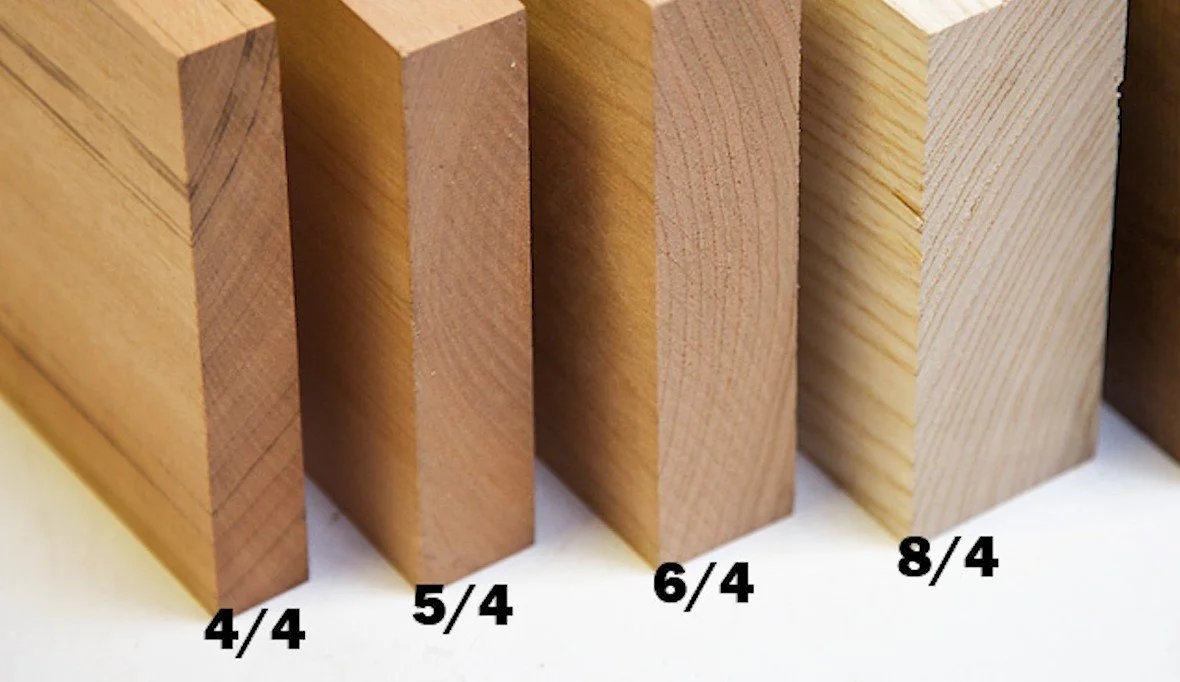

Of course, this is complete garbage. Anyone who has ever bought rough-sawn hardwood knows that it is sold by the quarter inch. A 1-inch board is called 4/4, 2 inches is 8/4, and so on. That system was based on how old mills were adjusted using a system of notches. If you wanted a 2-inch thick board, the operator moved the saw eight quarter-inch notches past zero, and you got 8/4 lumber.

Do you know what else the mill operator could do if he was so inclined and wasn’t part of a deep, international conspiracy that went directly to the top? He could move the blade two more notches and cut some 10/4 lumber. Now, I’m no math whiz, but 10/4 is 2-1/2 inches. If you dried and planed a quarter inch from each of those surfaces, your boards would be… carry the one… 2 inches thick. What do you know, an actual 2X4!

It wasn’t that they couldn’t do it. It wasn’t even that they didn’t want to waste the wood. They just didn’t want to waste THEIR wood. Instead, they wanted to waste YOUR wood by charging you for the water and sawdust that was left behind at the mill.

Time to Take a Stand

I used to fall for this scam. I, like you, was once just another fly in the lumber barons’ web. I believed all of this was justified because you were paying for the drying and planing services the mill did on your behalf. You want dry, straight wood, don’t you?

But when was the last time you bought a dry 2X4? I have a pile of them in my warehouse right now that are half the weight they were when I brought them home, and every one of them is twisted and bowed like a bunch of arthritic bananas.

No, big lumber pulled one over on us generations ago, and it’s time to take a stand. You can bet I’ll be letting out an audible sigh the next time I go to the lumber yard, and I don’t care who hears it.

My Table Saw and Bandsaw are AWSOME! Check them out at Harvey Woodworking Machinery: https://www.harveywoodworking.com/

My hand tool collection includes premium tools from Bridge City Tool Works: https://bridgecitytools.com/

Please help support us by using the link above for a quick look around!

Some other useful links: -Check out our project plans.

★SOME OF MY FAVORITE INEXPENSIVE TOOLS★

(If you use one of the affiliate links below, we may receive a small commission)

#ISOtunes Hearing Protection (Save 10%): https://shop.isotunes.com/stumpy

BOW Featherboards: https://amzn.to/430ldhv

123 Blocks: https://lddy.no/vpij

Mechanical Pencils: https://amzn.to/2PA7bwK

Lumber pencil: https://amzn.to/2QtwZjv

Pocket Measuring Tape: http://amzn.to/2kNTlI9

Nut/Bolt/Screw Gauge: http://amzn.to/2CuvxSK

Self-Centering Bits: https://amzn.to/2xs71UW

Steel Ruler: https://lddy.no/10mv7

Center-Finding Ruler: https://lddy.no/10nak

Bit & Blade Cleaner: https://amzn.to/2TfvEOI

Narex Chisels: https://lddy.no/sqm3

Mini Pull Saw: https://amzn.to/2UEHBz6

Shinwa Rulers: https://lddy.no/zl13