How leather and paste can keep you sharp for a long time.

NOTE: Scroll to the bottom of this page to watch a video version of this tutorial and to find links to things mentioned in the video.

There is so much misinformation out there about stropping your woodworking tools, even I was confused for a long time. Does stropping make tools sharper? Is it necessary for woodworkers? Will soft leather round over the edge? Why not use MDF instead? What about charging strops with paste?

I’ll try to cut through the nonsense and answer those questions so you can get the edge you need with minimal expense and hassle.

Does stropping make tools sharper?

My great-grandfather’s razor and strop used to hang from a post, and I remember how he’d pull the leather tight with one hand and stroke the razor back and forth across its surface. He’d do a few strokes on each side every time he shaved. What was he doing?

I hear many people say stropping was just intended to remove the wire edge left behind by a sharpening stone. The wire edge, or burr, is the last remnants of steel that the stone pulled away from the cutting edge and left loosely connected like a fine wire. But my great grandfather didn’t create a lot of wire edges because he only occasionally used a stone on his razor.

The strop had a more complex purpose and it’s the key to understanding how a strop can be valuable tool for woodworkers.

A straight razor is a bit different than a woodworking tool. It has an edge so micro-thin that the whiskers on your face can bend and mash the steel so that it becomes wavy. The outer surface of the steel can also form microscopically shallow scratches and even fine chips.

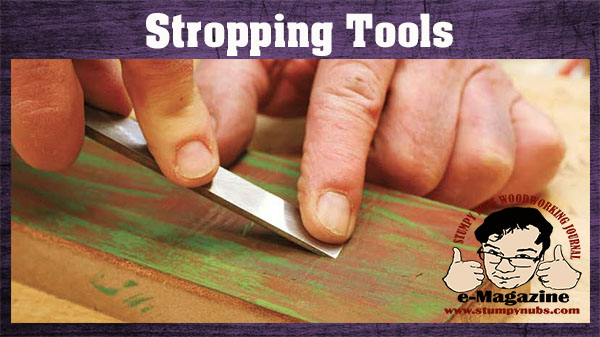

By stroking a razor’s edge back and forth on a leather strop you are re-aligning that steel, bending it back in place so it will cut cleanly again. You’re also burnishing the edge, moving the surface of the steel around to fill in some of the microscopic nicks that may have formed. And depending on the material you’re stropping with, you may also be abrading the steel, wearing away some of those fine chips and scratches.

Granted, the edge of a chisel is not nearly as thin as the edge of a straight razor, but a strop can still do the same three things- it can change the alignment of the steel, it can burnish or move the surface of the steel around and it can abrade the steel away to remove flaws. If we as woodworkers utilize these capabilities properly, we can get razor sharp edges as quickly and cheaply as our ancestors did.

Why strop with leather?

I hear some modern woodworkers saying you should just use plain old wood for stropping. The old timers had wood. So why did they use leather instead?

Because good quality, vegetable tanned leather is unique. It is much smoother than wood, but it also contains natural silicates making it a very fine abrasive. Wood contains silica as well, but you need only rub your hand on a piece of nice leather to see the difference.

Many strops are made from horse or cow hide. One side has a rough surface, the other is made smooth and shiny by repeated compressing under smooth glass rollers.

Before an edge got dull an old-timer would strop it on the shiny surface because it’s just hard enough to bend and re-align an edge, just abrasive enough to wear off a tiny bit of steel and just smooth enough to burnish and polish what’s left.

Of course, for that to be effective he always had to keep his edge nearly razor sharp. Otherwise he’d need a more aggressive strop like linen, or he was forced to go back to the stones.

Today, instead of using a more aggressive linen strop we can just flip the leather over and use the rougher surface on the back. We can also apply abrasive pastes to the rough side. We’ll talk about pastes later. But that’s what makes leather uniquely useful as a stropping material. The rough side holds compound better than wood or MDF, and the smooth side is just the right surface for the finest honing.

Will soft leather roll over my cutting edge?

Some folks say it’s better to use MDF than leather because the surface of MDF is hard, while leather is soft. And if you press a tool against a soft material you may compress and curl a bit of it up against the edge you’re trying to sharpen, effectively dulling it.

In theory, this can be true. Especially if you use a very soft leather that compresses easily. But let’s go back to the barber’s strop. He may pull it tight, and there’s some technique involved to avoid rolling over the edge altogether. But even if he’s careful a leather belt is still going to deflect with each stroke, wrapping around the edge more than a stiff piece of leather on a flat surface will compress. How can a barber get an edge sharp enough to shave your face if he’s dulling it with every stroke?

Because there’s a fine line between blunting an edge and dulling it. A sharp edge occurs where two planes meet. To be perfectly sharp those two planes would have to keep going and going until the steel at the meeting point is merely atoms thick. How long do you think an edge that thin would last? Not at all.

On the other hand, if those planes meet at a thicker point, the edge will be more durable. I’m not talking about taking your edge and rounding it right over, I’m just saying the slight deflection of the leather combined with the light abrasiveness of the honing compound is not enough to dull the tool more than it sharpens it.

That said, if you use very soft leather, or you really bear down on it, you could have problems. And that’s why some people use MDF instead. I’ve done my share of MDF honing too. I’m not saying that’s wrong if it works for you. But I find that rough side of the leather holds the compound better.

What abrasive compound should you use?

There are quite a few options out there when it comes to adding abrasive compounds to your strops. There are diamond pastes, but those seem a little pricey for me and as we’ll discuss shortly, stropping is really a good way to save money, not spend more of it.

One thing I’ve used a lot of in the past are abrasive sticks. These are a mixture of minerals and wax, and many of them can be identified by their color.

Black emory is one of the most aggressive. It’s grit size is about 25-35 microns, which is comparable to an 800 grit diamond stone. Since I sharpen with a 1000 grit stone before I strop, black emory compound would be a step backward.

White rouge typically contains aluminum oxide and is often 8-15 microns in size, or comparable to a 2000 grit diamond stone.

Brown tripoli is about 4-8 microns or 4000 grit

Red rouge is about 2-4 microns or 8000 grit.

The green or gold sticks you see a lot these days are sometimes around 1 micron or smaller, which is comparable to 10,000 or finer grit.

I say sometimes because you never know for sure. Manufacturers don’t always tell you what’s in their compounds. Some claim there compound is ultra-fine, but cuts very quickly. I can tell you this- if it cuts really fast, it probably contains some coarser particles.

I’ve also heard of folks using auto body pastes and rubbing compounds. Which should you use?

You must find a balance between something that’s fast enough and fine enough for your tastes. I wouldn’t go courser than about 5000 grit. That would encompass red, green, gold or even some of the pastes like the Trend stuff I use (affiliate link). That is unless you’re going to use multiple strops with progressively finer pastes.

Can stropping save you time and money?

We live in a world with a lot of sharpening options. You can buy ceramic water stones with grits into the tens of thousands. Why would you want to use a leather strop?

Because it will do the job with less hassle and less money. A 10,000 grit water stone will cost you over a hundred bucks. You must maintain it to keep it from dishing out as you use it. They can make a mess sometimes. And eventually it’s going to wear away on you.

A chunk of leather like this will cost you a few bucks depending on where you get it. The paste will cost a bit more but lasts for years. There’s no maintenance, no mess.

Here’s my sharpening process:

If I have a really beat up edge, I’ll grind a new bevel with a power tool. Then I sharpen it on a 1000 grit diamond stone (affiliate link), which also requires zero maintenance. I can go right from the diamond stone to the strop for final honing. Sometimes I take a dozen strokes with a coarse paste like brown tripoli. Then I use another strop with an extra-fine paste, and finish with a few strokes on the clean shiny side of the leather.

It’s just like working through the grits of sandpaper or water stones, except I only need to invest in a single stone. If you want to keep it really simple, use one stone and one strop with one paste on the rough side, and no paste on the shiny side.

After that, the key is keeping the tool honed honed. Return frequently to the strop and you’ll have to use the stone less and the grinder hardly at all. That’s fast, easy and cheap.

LINKS WORTH CHECKING OUT:

(We may make a small financial gain if you use these affiliate links)►

5-Grit abrasive compound sticks: https://amzn.to/2x6nOwx

Trend 300/1000 grit diamond stone stone: http://amzn.to/2nBdaq5

Trend lapping fluid: http://amzn.to/2nknjF8

Leather strop material: https://amzn.to/2IXf2n8

Trend mirror paste: https://amzn.to/2TXM3G6

When you use this link to visit our sponsor, you support us►

Trend diamond stones: https://amzn.to/2XomWMi

Follow us on social media►

Instagram: https://www.instagram.com/stumpynubs/

Twitter: https://twitter.com/StumpyNubs

Facebook: https://www.facebook.com/Stumpy-Nubs-Woodworking-Journal-305639859477973/

Facebook: https://www.facebook.com/Stumpy-Nubs-Woodworking-Journal-305639859477973/