How to choose the right diamond stone in a world where you get what you pay for.

NOTE: Scroll to the bottom of this page to watch a video version of this tutorial and to find links to things mentioned in the video.

At first, diamond sharpening stones may seem pretty straightforward- flat plates with grit on them. They’re simply man made stones, right? Actually, there’s more to them than you may realize. And it’s important that you understand some basic facts about diamond stones if you hope to get great results without wasting a lot of your hard-earned money.

Here are some answers to common questions regarding how diamond stones work, how they are made, and how you can choose the right one:

Why are diamond stones so popular?

I think that’s a matter of opinion. But for me it comes down to two things: They are easy to maintain, and they work fast. Unlike traditional stones, a diamond plate doesn’t become “dished out” as you use it. That means you won’t have to re-flatten it between uses, as you would a traditional water or oil stone. And since diamonds are one of the hardest materials on earth, they cut steel very quickly. They may even be used to sharpen carbide router bits and cutters.

Are those real diamonds?

All the stones I have ever used are covered with man made “micro diamonds”. There are a couple different processes that may be used to create them, but they generally involve chemicals, gasses, carbon and heat. Diamonds are literally grown on a substrate in a special chamber. They are sifted to separate them by size and attached to a plate for your sharpening convenience.

Do the type of diamonds matter?

Some diamond stones are created with what are called “polycrystalline diamonds”, while others utilize “monocrystalline diamonds”. The surface of a polycrystalline diamond is covered with tiny points and sharp edges. These edges fracture during use, exposing new sharp edges. This is great for very fine polishing pastes but not so much for diamond sharpening stones because as polycrystalline diamonds fracture, they become smaller. Suddenly your 300-grit stone becomes something entirely different. That’s why high-quality diamond stones are made with monocrystalline diamonds. These are more expensive to produce, but they maintain their size and shape during use. It takes a very long time for this type of diamond stone to wear out.

Electroplating vs. adhesives- which are better?

The quality of your stone is only as good as the adhesion between the diamonds and the substrate. Manufacturers of cheap stones merely sprinkle the diamond bits onto a layer of adhesive. These stones may look and even feel fine at first, but they won’t last. Good diamond stones are electroplated. A metal plate is dipped into a solution of heated nickel and diamonds, then an electrical current is passed through the solution causing it to bond with the metal plate. This process embeds about two thirds of each diamond into the nickel layer. Like an iceberg, most of the diamond is locked beneath the surface, making it very difficult to remove. Electroplated diamond stones have a far longer lifespan than those made with adhesives.

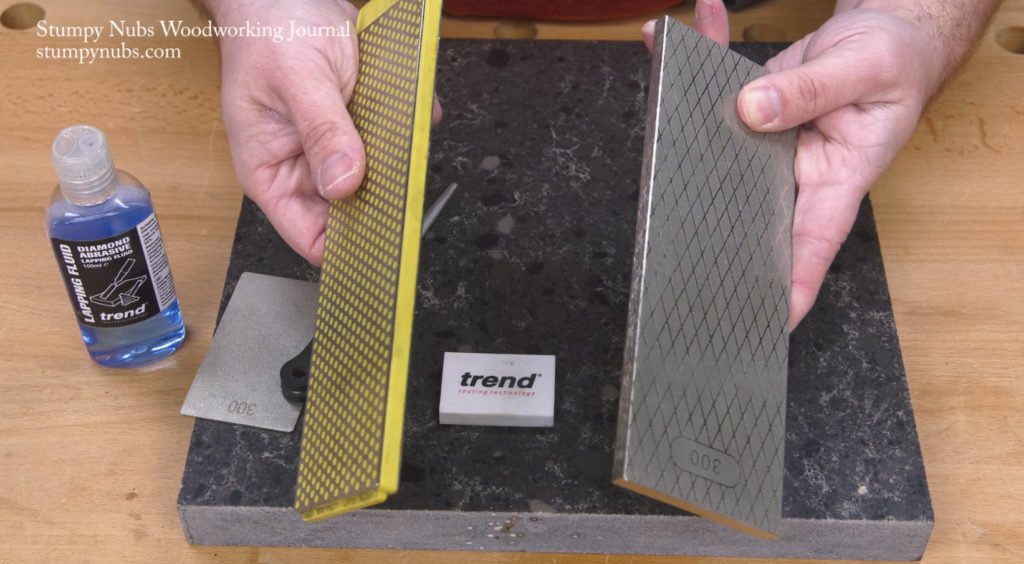

Are plastic plates as good as all metal plates?

For any sharpening stone to work well for chisels and plane irons, it must be perfectly flat, and it must remain that way. To save money, many manufacturers attach their diamonds to a thin metal plate, which is in turn attached to a thicker block of plastic. These plastic plates are molded, not machined. They are rarely flat. Other manufacturers attach their thin metal plates to a thicker machined metal base. But frankly, that defeats the whole purpose. Not only do adhesives compromise the plate’s flatness, but moisture may seep between the layers over time, introducing rust that can affect flatness or even cause delamination. A good diamond stone should be a single plate of steel, precisely machined to better than +/- 0.001”. (The process of electroplating the diamonds will slightly decrease the level of flatness, so the plate itself should really be approx. +/- 0.0005” if you hope to achieve +/- 0.001” in the end product.) Only then can you be sure that it will be flat and remain so over time.

Should I use my diamond stone dry?

Some companies say you may use their stones dry. While this will not harm the diamonds, it’s rarely a good idea. As material is removed from your blade, it must go somewhere. A liquid lubricant will create a swarf that will carry the fine shavings away so they won’t clog up the tiny spaces between the diamonds, which would quickly cause them to stop cutting.

Should I use water on my diamond stone?

Some companies recommend water as a lubricant. I think this is a bad idea, and I’m not alone in that theory. It is never a good idea to introduce water to metal unless you are sure you can get it completely dry every time. This isn’t easy. Water is likely to remain deep in the grit which may seep into the nickel used to embed the diamonds. If moisture makes its way to the steel substrate it may lead to corrosion and loose diamonds. This problem will be compounded if your stone is made from two or more layers.

What about light oil, kerosene or WD-40?

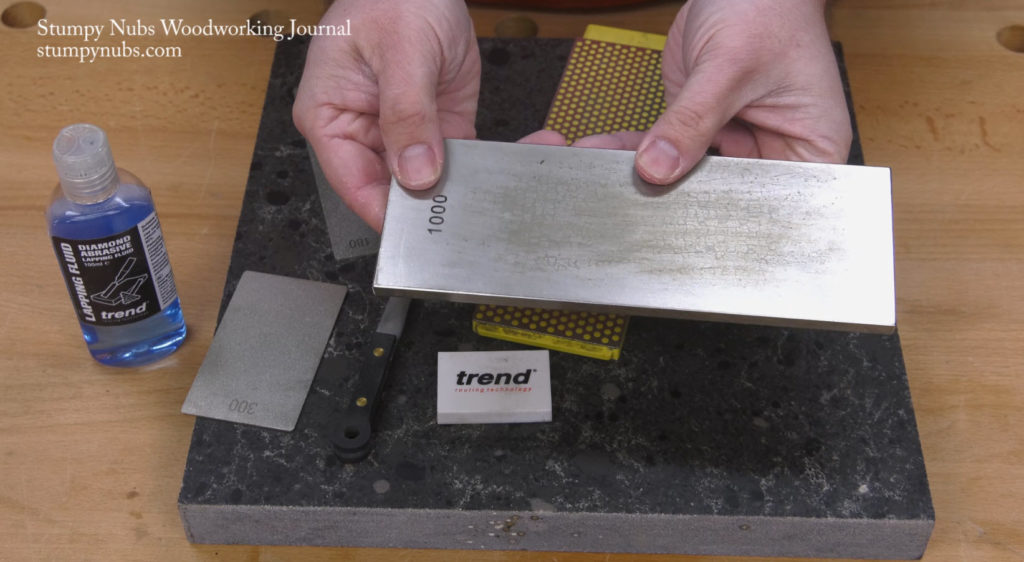

Fine stones (1000 grit) feature diamonds that are about 15 microns in size. Since about two thirds of the diamond is embedded in the stone the valleys left between the diamonds are only about 5 microns deep. According its materials safety data sheet, WD-40 leaves a film of 17 microns. Needless to say, that is thicker than the valleys are deep. So, while light oils like WD-40, 3-in-1 oil or kerosene may be fine for very course stones, they are too thick for fine grits. Using them will reduce the stone’s effectiveness.

What diamond stones do you recommend?

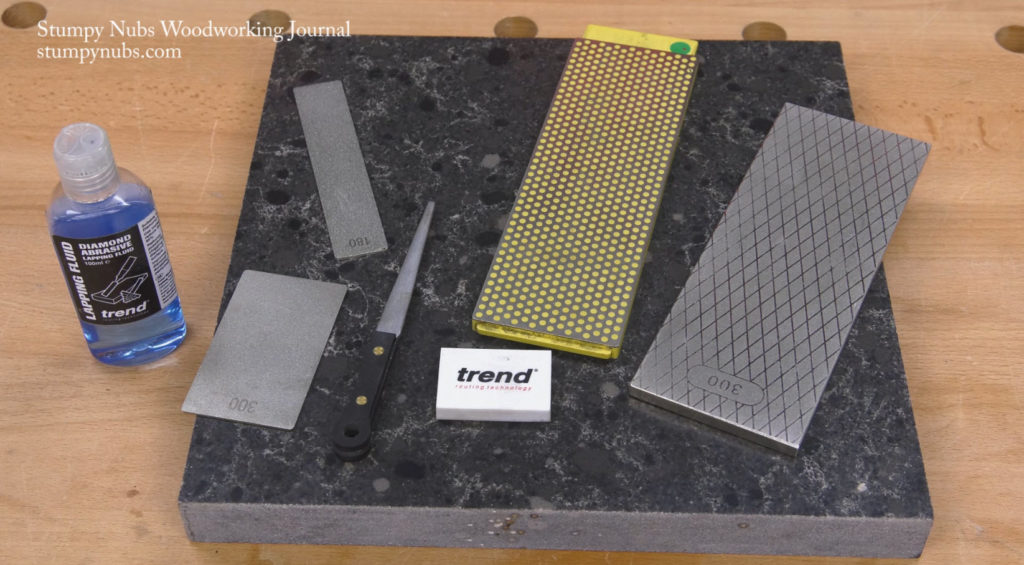

I have become partial to the Trend stones (affiliate link). They meet all the standards I laid out above Trend stones are a single piece of thick steel. They are machined to +/- 0.0005”, the flattest in the industry. The monocrystalline diamonds are securely embedded with an electroplating process. They aren’t cheap because they didn’t cut any corners. But even with daily use they will last about a decade, much longer in the average garage workshop, so the investment doesn’t hurt so much. Now, I must admit that I personally know the guys at Trend, and they are a sponsor of our website. But I was using their products before they were a sponsor. And I can honestly say that they work as advertised.

What grits do you recommend?

I use a 300-grit stone to create a new bevel, and follow up with 1000-grit. As a final step I use a leather strop with a polishing compound to finish the edge. Why 300/1000? Because those happen to be the two grits on my double-sided stone (affiliate link). Frankly, it doesn’t matter as much as you think. 300 grit is nice because it works faster than 600, but it’s not so course that you have to spend all day on the 1000 grit to remove the 300 grit scratches. 1000 grit is sharp enough, especially if you follow up with the strop. I know some people like to fuss over grits, and water stones may go into the tens of thousands. But wood is an abrasive material. After a couple of strokes your 20,000 grit edge is going to be worn down to 1000 or less anyway. If 1000 followed by a light stropping is sharp enough to shave the hair off my arm, it’s sharp enough to shave wood fibers.

Only one double-sided stone?

These things aren’t cheap, why buy more than you need? Of course, there are some great diamond accessories on the market for special applications, such as files and credit card hones (affiliate line). I use them as needed. But most straight edged tools can be sharpened with the single stone and strop.

What’s the bottom line on diamond stones?

If you sharpen your tools by hand you may want to check into diamond stones. They require almost no maintenance and they cut steel fast. If you do decide to buy diamond stones, insist that they be made with monocrystalline diamonds that are electroplated to the surface of a single piece of machined steel. No glue, no layering. Avoid using your stones dry, stay away from water, and if your fine grits are cutting slowly it may be the type of lubricant you are using. Finally, you can get by just fine with a 300/1000 or similar double-sided stone (affiliate link) and a leather strop for just about every woodworking tool.

LINKS WORTH CHECKING OUT:

(We may make a small financial gain if you use these affiliate links)►

Trend 300/1000 grit stone: http://amzn.to/2nBdaq5

Trend lapping fluid: http://amzn.to/2nknjF8

Trend Tool & Bit cleaner: http://amzn.to/2dZkJl3

Trend Kit/C (for router bits, forstner bits, etc.): http://amzn.to/2nhNLi7

When you use this link to visit our sponsor, you support us►

Trend diamond stones: https://amzn.to/2XomWMi

Follow us on social media►

Instagram: https://www.instagram.com/stumpynubs/

Twitter: https://twitter.com/StumpyNubs

Facebook: https://www.facebook.com/Stumpy-Nubs-Woodworking-Journal-305639859477973/